Brief Summary

This video provides an overview of the crude oil refining process, explaining the three main stages: separation, reaction/conversion, and purification. It details the equipment and processes used to transform crude oil into various valuable products like gasoline, diesel, and jet fuel, while also addressing the removal of impurities and the optimisation of product quality.

- Crude oil refining involves separation, reaction/conversion, and purification.

- Atmospheric and vacuum distillation are key separation techniques.

- Hydrotreating removes sulfur, while isomerisation and reforming enhance gasoline quality.

- Blending optimises product mix based on market demands.

Introduction to Crude Oil Refining

The video introduces the complex process of crude oil refining, which is divided into three main stages. These include separation, reaction or conversion, and purification. The goal is to achieve low sulfur content and specific octane ratings in the final products.

Pre-treatment and Atmospheric Distillation

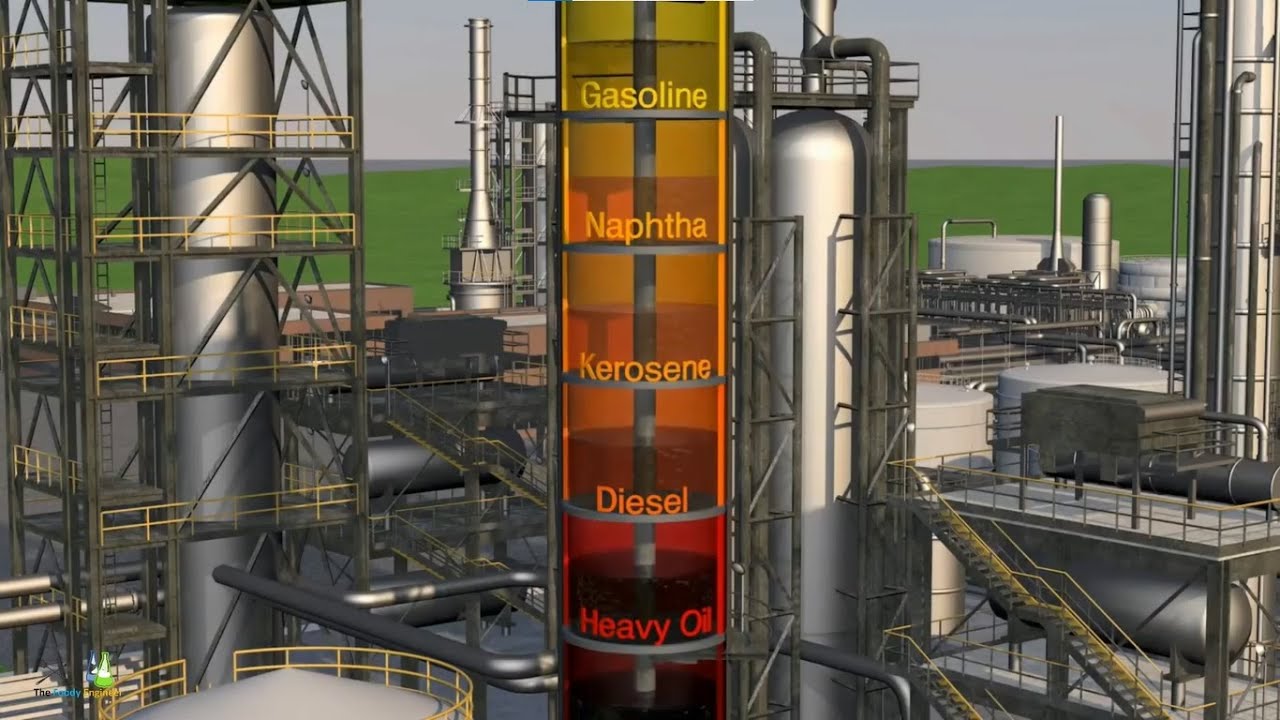

Before crude oil enters the atmospheric distillation unit, it undergoes pre-treatment in tanks equipped with mixers to prevent sedimentation. The oil is then pumped through a desalter to remove chlorides, which can form corrosive hydrochloric acid during the refining process. The crude oil then enters the atmospheric distillation column, the core of the separation process. Here, components are separated based on their boiling points, yielding fractions like gas, light naphtha, heavy naphtha, jet fuel (avtur/kerosene), diesel oil, and atmospheric residue. The process typically stops at 540°C to prevent the breakdown of paraffinic hydrocarbons into olefins, which are undesirable in this stage.

Vacuum Distillation and Hydrotreating

The residual from atmospheric distillation is further processed in a vacuum distillation unit to prevent the cracking of hydrocarbons at high temperatures. This unit operates under vacuum to lower the boiling points of the fractions. The resulting products then undergo hydrotreating to remove sulfur with the help of hydrogen and catalysts like cobalt-molybdenum. This process converts sulfur into H2S, which is then separated. The conditions in hydrotreating become more severe (higher pressure and temperature) for heavier fractions like diesel.

Gas Sweetening, Isomerisation and Reforming

Gases from hydrotreating undergo amine treating to remove sulfur compounds, producing elemental sulfur through a Claus process. Light fractions are processed in a Merox treater. The process of isomerisation converts paraffins into isoparaffins to improve the octane number. Catalytic reforming uses catalysts to convert paraffins and naphthenes into aromatics, which have high octane ratings. This process requires low sulfur content, achieved through hydrotreating, and uses catalysts like nickel.

Gasoline Blending and Cracking Processes

The products from isomerisation and reforming are blended to create final gasoline products with desired octane numbers. Online analysers regulate the blending process to meet market demands, balancing production and sales. For heavier fractions, cracking processes like hydrocracking and fluid catalytic cracking (FCC) are used to break down larger hydrocarbon molecules into smaller, more valuable ones. Hydrocracking uses hydrogen, while FCC uses catalysts. These processes yield butane, naphtha, and light cycle oil.

Residue Processing and Hydrogen Production

Residues from cracking can be further processed to extract more naphtha. The production of hydrogen, essential for hydrotreating and hydrocracking, is achieved through steam methane reforming (SMR), which converts natural gas and steam into hydrogen and CO2. Refineries without cracking units may not require hydrogen synthesis.