Brief Summary

This video explains the function, usage, and variations of the clutch on power drills. It covers when to use the clutch, how it works mechanically, and five lesser-known facts about clutches, including the arbitrary nature of the numbered settings and the move towards electronic clutches. The video also provides practical demonstrations and comparisons between different drill brands.

- The clutch is primarily used for driving screws and fasteners, especially when precision is needed to avoid stripping or damaging materials.

- The numbered settings on a drill's clutch collar are arbitrary and vary between manufacturers, not representing specific torque units.

- Electronic clutches are becoming more common but are often less favored than mechanical clutches due to consistency and control issues.

When to Use the Clutch

The clutch on a drill should be used when driving screws or fasteners to prevent applying too much torque. It is especially useful for delicate tasks involving smaller screws, such as installing cabinet hardware or cup hinges, where over-tightening can strip the screw or damage the material. The clutch is also beneficial for pre-drilled and countersunk screws, allowing the user to apply just enough torque for the threads to grab without overtightening.

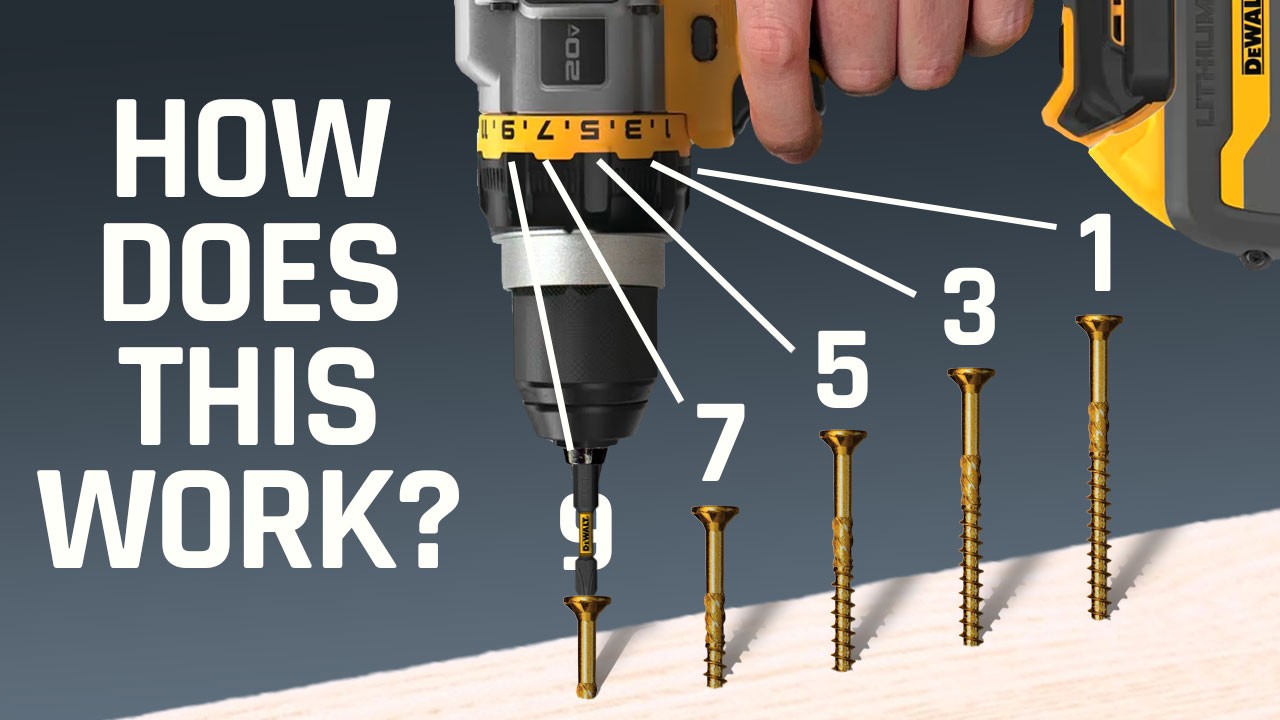

Demonstration of Clutch Settings

The presenter demonstrates the effect of different clutch settings by driving 2.5-inch screws into a Douglas fir 4x4 at each graduation on the drill's collar. The test reveals that some drills apply too much torque even at the lightest settings. A comparison is made between using the clutch and using the drill in full drill mode (no clutch), highlighting the significant difference in torque application and screw depth.

Inside the Drill: How the Clutch Works

The presenter explains that the pistol grip drill design has been around for over 100 years, while the clutch was invented in 1946 by Black & Decker (now Stanley Black & Decker). By cutting open a drill, the video shows how the clutch mechanism works internally. As the clutch collar is rotated, it adjusts the distance between a threaded shaft and the drill's body, controlling the amount of torque applied.

Mechanics of the Clutch

Inside the clutch collar, a spring compresses to provide resistance. On the opposite side of the housing, a metal plate with teeth engages or disengages with ball bearings inside the housing. The spring pushes the housing closer or further from the teeth on the metal ring, engaging or disengaging based on the amount of resistance. When a certain level of torque is reached, the clutch disengages to prevent over-driving.

Arbitrary Nature of Clutch Numbers

The numbers on the clutch collar are arbitrary and vary significantly between manufacturers and even between different drills from the same manufacturer. These numbers do not represent specific units of torque. They are simply graduations between the drill's full torque capability and the least amount it can produce.

Lack of Standardization

There is no standardization in the numbering system for clutch settings across different drills. The range of numbers can vary widely, such as one drill going up to 11 and another up to 24. This lack of consistency means users cannot assume that the same number on different drills will provide the same level of torque. It's important to always test the clutch setting, starting low and working up to the necessary resistance.

Electronic vs. Mechanical Clutches

The video highlights a shift towards electronic clutches, as found in drills like the DeWalt DCd 999 and Festool. Electronic clutches stop the drill and sometimes provide an audible signal when the set torque is reached. However, many users find electronic clutches less consistent and offering less control compared to traditional mechanical clutches, especially at lower settings. Demonstrations with both drills show that even on low settings, the electronic clutches can be quite aggressive, driving screws too far.