Brief Summary

This video provides a comprehensive guide to different types of screws commonly used in DIY and construction projects. It explains the anatomy of a screw and details the specific applications, features, and materials of wood screws, machine screws, drywall screws, self-drilling screws, concrete screws, cement board screws, deck screws, sheet metal screws, lag screws, and multipurpose screws. The video emphasizes the importance of selecting the right screw for the job to ensure a secure and durable hold.

- Understanding screw anatomy is crucial for selecting the right type.

- Different screws are designed for specific materials like wood, metal, drywall, and concrete.

- Features like self-drilling tips and corrosion-resistant coatings enhance performance in specific applications.

Introduction

The video introduces the topic of screws as fasteners, clarifying that "fasteners" is a broad term encompassing screws, nails, and bolts. The presenter aims to educate beginners on the various types of screws they will encounter in building and DIY projects. Understanding the anatomy of a screw is emphasized as crucial before exploring the different types.

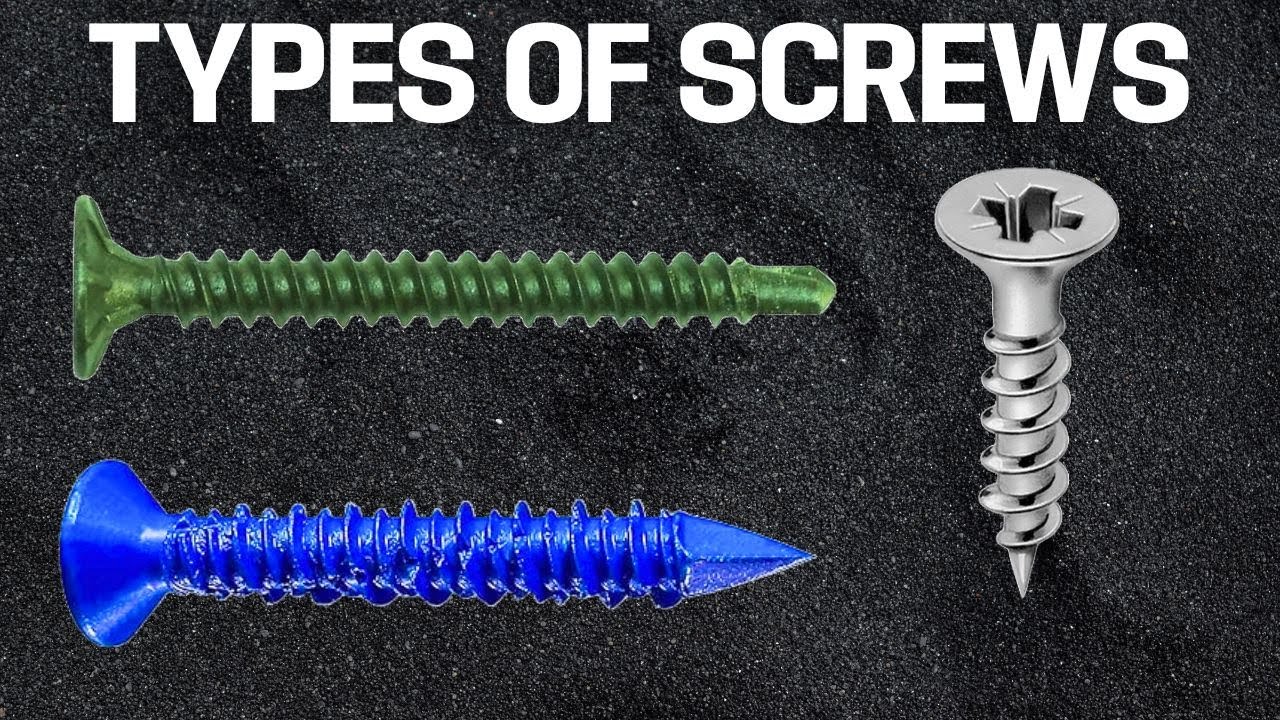

The Anatomy of The Screw

A screw consists of five main parts: the head, the drive (where the screwdriver or drill bit is inserted), the shank (the smooth area between the head and the thread), the threads, and the point. Knowing these parts is important because screws vary in each of these components, influencing their specific applications and performance.

Wood Screws

Wood screws are designed for fastening wood to wood and feature coarse threads for a strong grip and holding power. They have sharp points for easy and accurate insertion. These screws come in various head shapes and materials, with different steel grades offering varying levels of strength and load-bearing capabilities. The choice of material also depends on environmental conditions, with stainless steel being more corrosion-resistant than carbon steel. Wood screws are commonly used in cabinet making, furniture assembly, decking, and framing.

Machine Screws

Machine screws are designed for fastening metal to metal, featuring uniform threads along the entire shaft. They are used with a nut or in a tapped hole, which is a pre-made hole with internal threading. Unlike wood screws, machine screws are not self-tapping; they require the hole to be prepared in advance. These screws are commonly used in machinery, appliances, electronics, and the automotive industry.

Drywall Screws

Drywall screws are used to fasten drywall to wood or metal framing, and sometimes drywall to drywall. There are three types: screws for wood, screws for metal, and laminating screws for drywall-to-drywall connections. The screws for wood have coarse threads, while those for metal have fine threads. A distinctive feature of drywall screws is their bugle-shaped head, which prevents damage to the paper finish on the drywall surface. They are typically covered in black phosphate for corrosion resistance.

Self Drilling Screws

Self-drilling screws have a drill-like point that allows them to create their own pilot hole in metal, eliminating the need for pre-drilling. These screws are also self-tapping, creating their own internal threads as they are driven into the material. It's important not to confuse self-tapping and self-drilling. Some wood screws also have self-drilling tips to prevent the wood from splitting.

Concrete Screws

Concrete screws, also known as masonry screws or concrete anchors, are designed to fasten wood or metal to concrete, bricks, or blocks. They require a pre-drilled hole using a special drill bit, often used with a hammer drill. While not self-drilling, they are self-tapping, cutting their own threads into the concrete. Many concrete screws have a blue coating to increase corrosion resistance and durability.

Cement Board Screws

Cement board screws are used to fasten cement board to wood or metal framing. Cement board is more sturdy and water-resistant than drywall, making it suitable for use as an underlay in tile installations. Like drywall screws, cement board screws vary depending on whether they are used for wood or metal. The wood version has a high-low thread design, while the metal version has a self-drilling tip. These screws are designed for high-moisture areas and are more durable and corrosion-resistant than drywall screws.

Deck Screws

Deck screws are specifically designed for outdoor use on decks and fencing. Their key feature is that they are made with corrosion-resistant materials to withstand exposure to outdoor elements, preventing rust and corrosion. They come in various finishes.

Sheet Metal Screws

Sheet metal screws are designed for use with sheet metal, such as gutters and air ducts. Some have sharp, pointy heads to pierce through thin metals. They can also come with self-drilling points. These screws are available in different materials, sizes, and head shapes.

Lag Screws

Lag screws, also known as lag bolts, are heavy-duty wood screws used for securing heavy lumber, beams, and posts. They are larger in diameter than regular wood screws and have coarse threading for a strong grip. A distinctive feature is their hex-shaped head, which is installed using a socket wrench after pre-drilling a hole.

Multipurpose Screws

Multipurpose screws can be used on drywall, decking, metals, and wood. Some have self-drilling tips, while others have regular tips, making them versatile for various applications.